Abstract: The MAX1759 step-up/step-down charge-pump regulator is used to power white LEDs with constant current by clever use of a feedback network. The 1x/2x modes of the charge pump provides high efficiency, especially in two-cell NiMH and/or Alkaline applications.

Since their invention a few years ago, white light-emitting-diodes (LEDs) have been steadily gaining in popularity. Because they offer whiter light and longer life than incandescent bulbs and are easier to use than fluorescent tubes, they have been steadily gaining market share in a variety of lighting applications, such as flashlights and display backlighting in handheld electronics. However, white LEDs present their own set of technical issues.

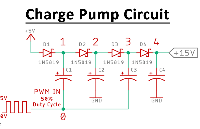

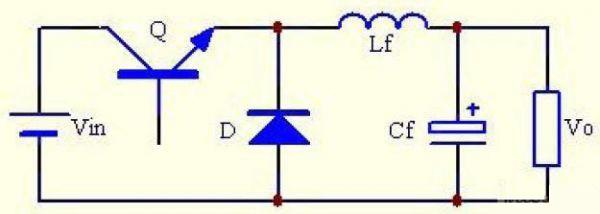

An obvious issue for battery-powered equipment is the high forward voltage of white LEDs, which is typically 3.6V at 20mA and is usually specified as 3.0V minimum to 4.0V maximum. Once the voltage-drop of ballast resistors is added, the required bias voltage is even higher; therefore, typical battery systems require a voltage boosting DC-to-DC converter. Recently, several IC manufacturers have introduced various charge-pump and inductor-based boost converter ICs dedicated to driving white LEDs; however, at the time of this writing, none of these ICs support low-voltage operation from a two-cell stack of NiMH or alkaline batteries. Also, some of these dedicated ICs fail to regulate properly or even shutdown properly when presented with a 5V input, such as from a wall adapter.

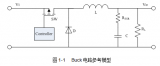

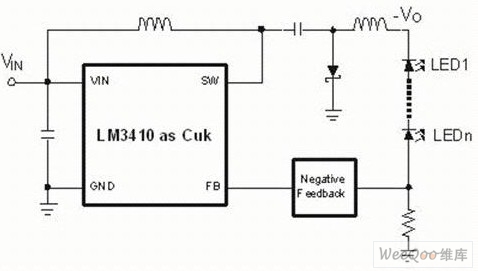

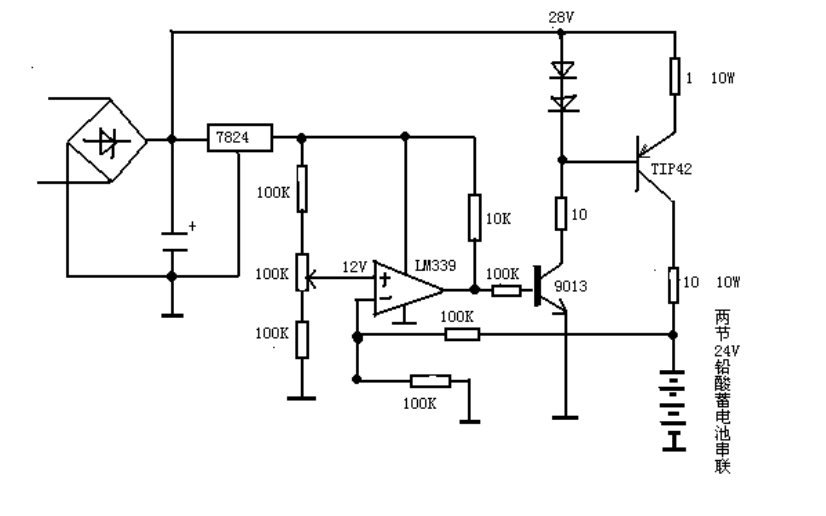

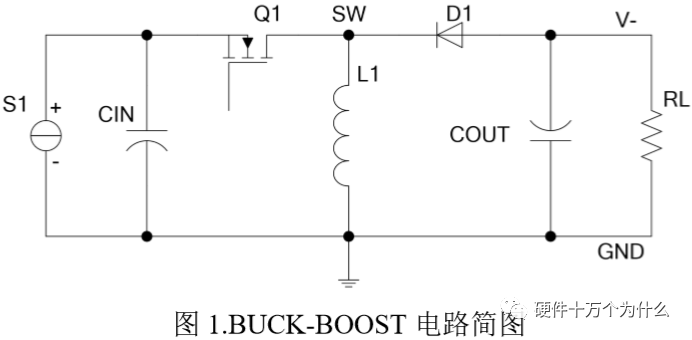

Although never intended for white LED bias applications, the MAX1759 buck/boost charge-pump is the first charge-pump to regulate white LEDs from a wide 1.6V to 5.5V input range. As implemented in the circuit of Figure 1, the MAX1759 will bias the LEDs with 15mA from inputs including two NiMH cells, two alkaline cells, three NiMH cells, three alkaline cells, a single Li+ cell, a regulated I/O voltage of 2.5V or 3.3V, a 5V wall adapter, or any combination of these for flexible systems. Unlike most charge-pumps, the IC incorporates a buck mode for proper regulation with 5V inputs, and internal circuitry fully disconnects the output in shutdown, eliminating LED leakage current and associated battery drain when off. Other features include PWM dimming via the active-low SHDN pin and fold-back current limiting for short-circuit protection.

Figure 1. The MAX1759 buck/boost charge-pump biases white LEDs with 15mA from a wide 1.6V to 5.5V input voltage range.

By utilizing the external feedback capability of the MAX1759 with a unique resistor connection, the bias voltage is automatically adjusted to minimize lot-to-lot or manufacturer-to-manufacturer variation of the LEDs. For more information on this feedback scheme, see the app note "LDO Improves White LED Ballasting".

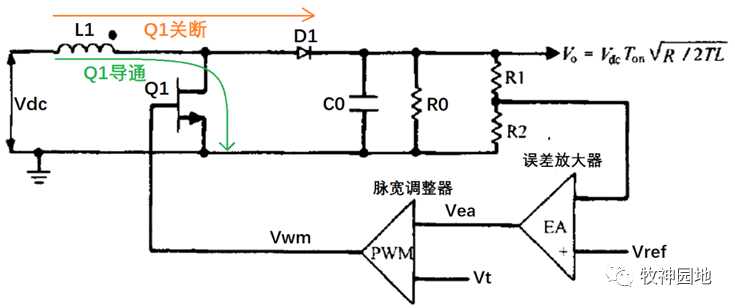

Efficiency and battery current vs. battery voltage are shown in Figure 2. The data was taken using very typical LEDs with 3.6V forward voltage at 20mA, and, therefore, some variation should be expected for non-typical LEDs. Because the boost mode uses a 2x charge-pump configuration, efficiency is optimized for two NiMH or alkaline cells. However, as can be seen from the data, some dimming of the LEDs is expected with very low input voltages below 1.9V. For 2-cell flashlights, this dimming at the end of battery life is desirable, since some warning of weak batteries is actually a safety feature.

Figure 2. The efficiency and battery current for the circuit of figure 1 varies with battery voltage, especially when transitioning from 1x buck mode to 2x boost mode at approximately 4.25V input.

Since their invention a few years ago, white light-emitting-diodes (LEDs) have been steadily gaining in popularity. Because they offer whiter light and longer life than incandescent bulbs and are easier to use than fluorescent tubes, they have been steadily gaining market share in a variety of lighting applications, such as flashlights and display backlighting in handheld electronics. However, white LEDs present their own set of technical issues.

An obvious issue for battery-powered equipment is the high forward voltage of white LEDs, which is typically 3.6V at 20mA and is usually specified as 3.0V minimum to 4.0V maximum. Once the voltage-drop of ballast resistors is added, the required bias voltage is even higher; therefore, typical battery systems require a voltage boosting DC-to-DC converter. Recently, several IC manufacturers have introduced various charge-pump and inductor-based boost converter ICs dedicated to driving white LEDs; however, at the time of this writing, none of these ICs support low-voltage operation from a two-cell stack of NiMH or alkaline batteries. Also, some of these dedicated ICs fail to regulate properly or even shutdown properly when presented with a 5V input, such as from a wall adapter.

Although never intended for white LED bias applications, the MAX1759 buck/boost charge-pump is the first charge-pump to regulate white LEDs from a wide 1.6V to 5.5V input range. As implemented in the circuit of Figure 1, the MAX1759 will bias the LEDs with 15mA from inputs including two NiMH cells, two alkaline cells, three NiMH cells, three alkaline cells, a single Li+ cell, a regulated I/O voltage of 2.5V or 3.3V, a 5V wall adapter, or any combination of these for flexible systems. Unlike most charge-pumps, the IC incorporates a buck mode for proper regulation with 5V inputs, and internal circuitry fully disconnects the output in shutdown, eliminating LED leakage current and associated battery drain when off. Other features include PWM dimming via the active-low SHDN pin and fold-back current limiting for short-circuit protection.

Figure 1. The MAX1759 buck/boost charge-pump biases white LEDs with 15mA from a wide 1.6V to 5.5V input voltage range.

By utilizing the external feedback capability of the MAX1759 with a unique resistor connection, the bias voltage is automatically adjusted to minimize lot-to-lot or manufacturer-to-manufacturer variation of the LEDs. For more information on this feedback scheme, see the app note "LDO Improves White LED Ballasting".

Efficiency and battery current vs. battery voltage are shown in Figure 2. The data was taken using very typical LEDs with 3.6V forward voltage at 20mA, and, therefore, some variation should be expected for non-typical LEDs. Because the boost mode uses a 2x charge-pump configuration, efficiency is optimized for two NiMH or alkaline cells. However, as can be seen from the data, some dimming of the LEDs is expected with very low input voltages below 1.9V. For 2-cell flashlights, this dimming at the end of battery life is desirable, since some warning of weak batteries is actually a safety feature.

Figure 2. The efficiency and battery current for the circuit of figure 1 varies with battery voltage, especially when transitioning from 1x buck mode to 2x boost mode at approximately 4.25V input.

电子发烧友App

电子发烧友App

评论