刹车灯(英文),Pulsing Third Brake Light

关键字:刹车灯(英文)

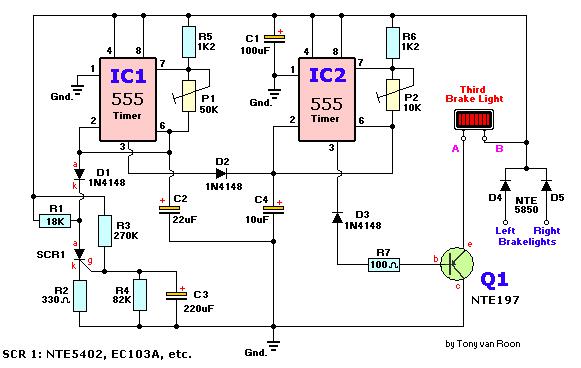

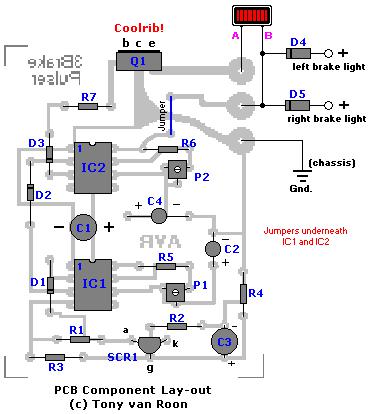

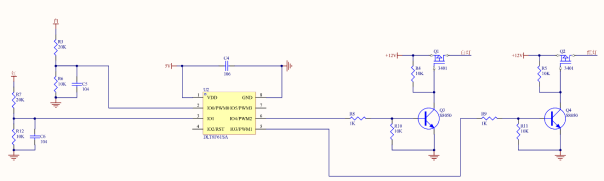

Circuit dijagram

Parts

IC1,IC2 = 555 Timer, RS #276-1723

SCR1 = NTE/ECG5402, RS #276-1067, EC103A, MCR104, etc.

Q1 = NTE/ECG197, SK3083, TIP125, or equivalent

D1,D2,D3 = 1N4148, 1N914, NTE/ECG519, RS #276-1122

D4,D5 = 1N5400, NTE/ECG5850, RS #276-1141, or equivalent

R1 = 18K

R2 = 330 ohm (RS #271-1315)

R3 = 270K

R4 = 82K

R5,R6 = 1K2

R8 = 100 ohm (RS# 271-1311)

P1 = 50K, 10-turn

P2 = 10K, 10-turn

C1 = 100µF/16V (RS# 272-1016)

C2 = 22µF/16V (RS# 272-1014)

C3 = 220µF/16V (RS# 272-1017)

C4 = 10µF/16V (RS# 272-1013)

Q1 is a PNP Silicon Audio Power Out/Medium Power Switch Transistor, 7A, with a TO-220 case. As long as you have a transistor which is close it will work fine. The SCR is a 100vrm, 0.8A, sensitive gate with a TO-92 case. Diodes D1, D2 and D3 are standard small signal diodes. Power diodes D4 and D5 are the 6A, 50prv types, cathode case. The 60vrm type will work as well. I used for IC1 & IC2 the LM555 type. P1 controls the 'on' and pulse-duration, P2 controls the pulse-timing.

IC1,IC2 = 555 Timer, RS #276-1723

SCR1 = NTE/ECG5402, RS #276-1067, EC103A, MCR104, etc.

Q1 = NTE/ECG197, SK3083, TIP125, or equivalent

D1,D2,D3 = 1N4148, 1N914, NTE/ECG519, RS #276-1122

D4,D5 = 1N5400, NTE/ECG5850, RS #276-1141, or equivalent

R1 = 18K

R2 = 330 ohm (RS #271-1315)

R3 = 270K

R4 = 82K

R5,R6 = 1K2

R8 = 100 ohm (RS# 271-1311)

P1 = 50K, 10-turn

P2 = 10K, 10-turn

C1 = 100µF/16V (RS# 272-1016)

C2 = 22µF/16V (RS# 272-1014)

C3 = 220µF/16V (RS# 272-1017)

C4 = 10µF/16V (RS# 272-1013)

Q1 is a PNP Silicon Audio Power Out/Medium Power Switch Transistor, 7A, with a TO-220 case. As long as you have a transistor which is close it will work fine. The SCR is a 100vrm, 0.8A, sensitive gate with a TO-92 case. Diodes D1, D2 and D3 are standard small signal diodes. Power diodes D4 and D5 are the 6A, 50prv types, cathode case. The 60vrm type will work as well. I used for IC1 & IC2 the LM555 type. P1 controls the 'on' and pulse-duration, P2 controls the pulse-timing.

Applying the Brakes:

When you first press the brakes, this circuit will turn on your 3rd brake light via the main brake lights. After about a second a series of short strobe pulses occur. The number of pulses range from approximately 1 to 10, depending on the setting of P1/P2 and when the brake pedal was applied last. After the pulses have been applied the third brake light assumes normal operation. The prototype was set for five flashes which seemed more than enough. Two days later I re-adjusted the trimmer potentiometers for 4 flashes--1/2 second pause--4 flashes. Looks pretty cool!

When you first press the brakes, this circuit will turn on your 3rd brake light via the main brake lights. After about a second a series of short strobe pulses occur. The number of pulses range from approximately 1 to 10, depending on the setting of P1/P2 and when the brake pedal was applied last. After the pulses have been applied the third brake light assumes normal operation. The prototype was set for five flashes which seemed more than enough. Two days later I re-adjusted the trimmer potentiometers for 4 flashes--1/2 second pause--4 flashes. Looks pretty cool!

Circuit Description:

The schematic consists of two 555 timer/oscillators in a dual timer configuration both setup in astable mode. When power is applied via the brake pedal, the brake light driver Q1 is switched on via the low-output pin 3 of IC2, and timer IC1 begins its timing cycle. With the output on pin 3 going high, inhibiting IC2's pin 2 (trigger) via D2, charge current begins to move through R3, R4 and C2.

When IC1's output goes low, the inhibiting bias on pin 2 of IC2 is removed and IC2 begins to oscillate, pulsing the third brake light via the emitter of Q1, at the rate determined by P2, R6, and C4. That oscillation continues until the gate-threshold voltage of SCR1 is reached, causing it to fire and pull IC1's trigger (pin 2) low. With its trigger low, IC1's ouput is forced high, disabling IC2's trigger. With triggering disabled, IC2's output switches to a low state, which makes Q1 conduct turning on the 3rd Brake Light until the brakes are released. Obviously, removing the power from the circuit at any time will reset the Silicon Controlled Rectifier SCR1, but the RC network consisting of R4 and C2 will not discharge immediately and will trigger SCR1 earlier. So, frequent brake use means fewer flashes or no flashes at all. But I think that's okay. You already have the attention from the driver behind you when you used your brakes seconds before that.

The collector/emitter voltage drop accross Q1 together with the loss over the series fed diodes D4/D5, will reduce the maximum available light output, but if your car's electrical system is functioning normally in the 13 - 14volt range, these losses are not noticeable.

The schematic consists of two 555 timer/oscillators in a dual timer configuration both setup in astable mode. When power is applied via the brake pedal, the brake light driver Q1 is switched on via the low-output pin 3 of IC2, and timer IC1 begins its timing cycle. With the output on pin 3 going high, inhibiting IC2's pin 2 (trigger) via D2, charge current begins to move through R3, R4 and C2.

When IC1's output goes low, the inhibiting bias on pin 2 of IC2 is removed and IC2 begins to oscillate, pulsing the third brake light via the emitter of Q1, at the rate determined by P2, R6, and C4. That oscillation continues until the gate-threshold voltage of SCR1 is reached, causing it to fire and pull IC1's trigger (pin 2) low. With its trigger low, IC1's ouput is forced high, disabling IC2's trigger. With triggering disabled, IC2's output switches to a low state, which makes Q1 conduct turning on the 3rd Brake Light until the brakes are released. Obviously, removing the power from the circuit at any time will reset the Silicon Controlled Rectifier SCR1, but the RC network consisting of R4 and C2 will not discharge immediately and will trigger SCR1 earlier. So, frequent brake use means fewer flashes or no flashes at all. But I think that's okay. You already have the attention from the driver behind you when you used your brakes seconds before that.

The collector/emitter voltage drop accross Q1 together with the loss over the series fed diodes D4/D5, will reduce the maximum available light output, but if your car's electrical system is functioning normally in the 13 - 14volt range, these losses are not noticeable.

Building Tips:

You can easily build this circuit on perfboard or on one of RS/Tandy's experimentors boards (#276-150), or use the associated printed circuit board listed here.

Keep in mind that Q1 will draw most likely 2 or 3 amps and mounting this device on a heat sink is highly recommended. Verify that the scr is the 'sensitive gate' type. In incandecent bulbs, there is a time lag between the introduction of current and peak brightness. The lag is quite noticeable in an automotive bulb, so the duration of a squarewave driving such a bulb should be set long enough to permit full illumination. For that reason, and because lamps and car electrical systems vary, adjustment via P1 and P2 is necessary to provide the most effective pulse timing for your particular vehicle.

The reason that the third light is connected to both brake lights is to eliminate the possibility of a very confusing display when you use your turn signal with the brakes applied.

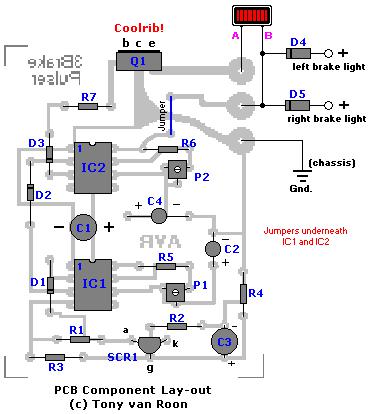

The cathode of D4 and D5 are tied together and go to point 'B' of the third brake light in the component layout diagram. Point 'A' goes to the other leg of the third brake light. Most if not all third brake lights in Canada & USA have two wires, the metal ones also have a ground wire which obviously goes to ground. I don't know the wiring schema for Australian and European third brake lights.

Don't forget the three jumpers on the pcb; two jumpers underneath IC1/IC2 between pin 4/8 and the one near Q1/R6.

If you use a metal case, don't forget to insulate the D4/D5 diodes.

Some 90's cars, like my 1992 Mercury Sable, have two bulbs inside the third brake light, each bulb is hooked up seperately to the left and right brake light for reasons only Ford knows. Click here for a possible 2-bulb hookup. It shows how I modified mine to get it working; and that was easier than I expected. Current draw with the two bulbs was measured at 1.85Amps (1850mA). Even with double the current none of the circuit components were getting hot. I had to re-adjust the two pots to make it flash since the bench testing was done with one bulb.

You can easily build this circuit on perfboard or on one of RS/Tandy's experimentors boards (#276-150), or use the associated printed circuit board listed here.

Keep in mind that Q1 will draw most likely 2 or 3 amps and mounting this device on a heat sink is highly recommended. Verify that the scr is the 'sensitive gate' type. In incandecent bulbs, there is a time lag between the introduction of current and peak brightness. The lag is quite noticeable in an automotive bulb, so the duration of a squarewave driving such a bulb should be set long enough to permit full illumination. For that reason, and because lamps and car electrical systems vary, adjustment via P1 and P2 is necessary to provide the most effective pulse timing for your particular vehicle.

The reason that the third light is connected to both brake lights is to eliminate the possibility of a very confusing display when you use your turn signal with the brakes applied.

The cathode of D4 and D5 are tied together and go to point 'B' of the third brake light in the component layout diagram. Point 'A' goes to the other leg of the third brake light. Most if not all third brake lights in Canada & USA have two wires, the metal ones also have a ground wire which obviously goes to ground. I don't know the wiring schema for Australian and European third brake lights.

Don't forget the three jumpers on the pcb; two jumpers underneath IC1/IC2 between pin 4/8 and the one near Q1/R6.

If you use a metal case, don't forget to insulate the D4/D5 diodes.

Some 90's cars, like my 1992 Mercury Sable, have two bulbs inside the third brake light, each bulb is hooked up seperately to the left and right brake light for reasons only Ford knows. Click here for a possible 2-bulb hookup. It shows how I modified mine to get it working; and that was easier than I expected. Current draw with the two bulbs was measured at 1.85Amps (1850mA). Even with double the current none of the circuit components were getting hot. I had to re-adjust the two pots to make it flash since the bench testing was done with one bulb.

Bench Testing:

I tested different semiconductors like the 1N5401/1N5404, NTE153, and 4A type powerdiodes for D4/D5. All worked very well. As expected, Q1 is getting very hot. Current draw was measured between 680 - 735mA with a regular automotive 'headlight' bulb, extra heavy duty to make sure the circuit was safe. I tested several other power transistors including some darlingtons like the TIP125 and the TIP147. I eventually settled for the TIP125 myself because I had it available but any thing with 5A or more will do fine.

The actual third brake bulb is a lot smaller. Adjusting the trimpots (P1/P2) may take a bit of patience but really fine-tunes the circuit well. The only drawback of this circuit is the discharge lag coming from the electrolytic capacitor C2 and the R4 resistor. Especially if the brakes are used often or at short intervals the third brake light will not flash or maybe flash once or twice. Again, this is because the R-C combo does not have enough time to discharge in between braking. It takes about 12 seconds to discharge C2.

The pcb measures 2 x 2.5 inch (5 x 6.4cm or 170 x 200 pixels)

at 2 colors and is shown smaller when you print these pages.

If you need a direct, full size copy of the pcb I suggest to load the gif file into a program like Paint Shop Pro or one of the many gif viewers available.

The layout is enlarged a bit for a better component view. Note that Q1 is drawn soldered on the pcb but if you have a metal case you can put it anywhere on the metal case (as a coolrib) and use havy duty wiring between Q1 and the PCB.

I tested different semiconductors like the 1N5401/1N5404, NTE153, and 4A type powerdiodes for D4/D5. All worked very well. As expected, Q1 is getting very hot. Current draw was measured between 680 - 735mA with a regular automotive 'headlight' bulb, extra heavy duty to make sure the circuit was safe. I tested several other power transistors including some darlingtons like the TIP125 and the TIP147. I eventually settled for the TIP125 myself because I had it available but any thing with 5A or more will do fine.

The actual third brake bulb is a lot smaller. Adjusting the trimpots (P1/P2) may take a bit of patience but really fine-tunes the circuit well. The only drawback of this circuit is the discharge lag coming from the electrolytic capacitor C2 and the R4 resistor. Especially if the brakes are used often or at short intervals the third brake light will not flash or maybe flash once or twice. Again, this is because the R-C combo does not have enough time to discharge in between braking. It takes about 12 seconds to discharge C2.

The pcb measures 2 x 2.5 inch (5 x 6.4cm or 170 x 200 pixels)

at 2 colors and is shown smaller when you print these pages.

If you need a direct, full size copy of the pcb I suggest to load the gif file into a program like Paint Shop Pro or one of the many gif viewers available.

The layout is enlarged a bit for a better component view. Note that Q1 is drawn soldered on the pcb but if you have a metal case you can put it anywhere on the metal case (as a coolrib) and use havy duty wiring between Q1 and the PCB.

CORRECTION: SCR1's anode/kathode

were shown reversed (fixed: 2-26-2000).

were shown reversed (fixed: 2-26-2000).

Author: Tony van Roon

声明:本文内容及配图由入驻作者撰写或者入驻合作网站授权转载。文章观点仅代表作者本人,不代表电子发烧友网立场。文章及其配图仅供工程师学习之用,如有内容侵权或者其他违规问题,请联系本站处理。

举报投诉

发布评论请先 登录

相关推荐

汽车制动系统如何提升刹车性能

汽车制动系统的刹车性能是确保行车安全的关键因素之一。为了提升刹车性能,可以从以下几个方面进行改进和优化: 一、选用高性能制动部件 刹车片 : 原厂刹车片通常采用少金属配方,摩擦系数较低

Melexis推出超低功耗霍尔效应开关芯片MLX92235

Melexis 推出超低功耗霍尔效应开关芯片MLX92235,该产品以卓越的可靠性和高度可预测的输出更新率公差,为汽车微功率应用领域带来重大突破,可广泛应用于车门把手、电子锁存器、遮阳板控制、信息娱乐系统按钮以及刹车灯开关等多种场景。

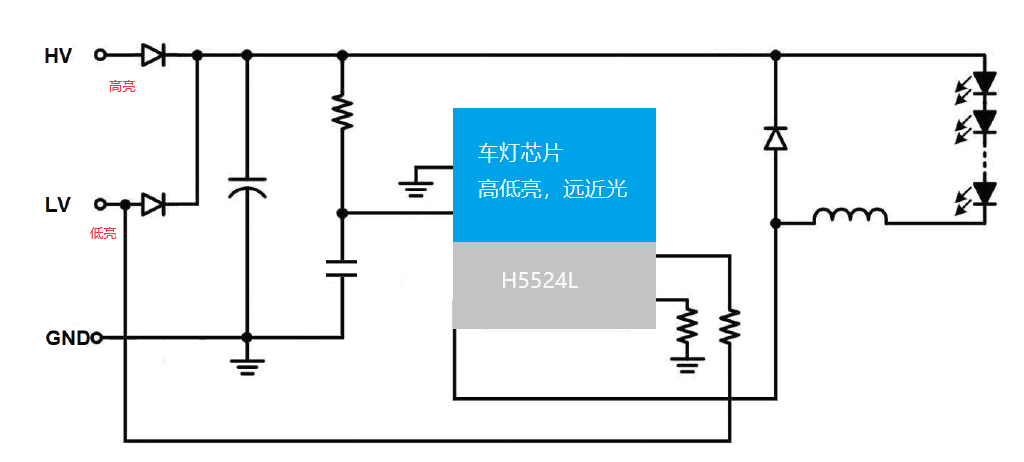

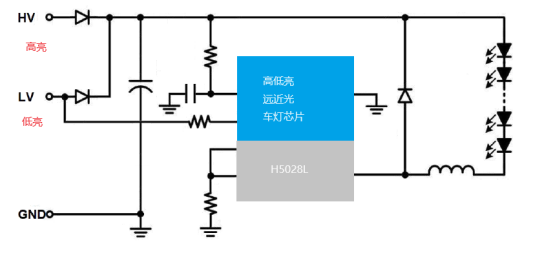

基于LED驱动器的汽车LED照明方案

LED照明因其高亮度、低能耗、长寿命及快速响应等特点,在汽车行业被广泛采用。LED前大灯、日间行车灯、刹车灯和转向灯等已成为众多车型的标准配置。同时,随着智能驾驶威廉希尔官方网站

的进步,汽车LED照明方案也在向

让汽车LED照明无死角,LED驱动的全面进化

以下文章来源于安森美,作者安森美LED照明因其高亮度、低能耗、长寿命及快速响应等特点,在汽车行业被广泛采用。LED前大灯、日间行车灯、刹车灯和转向灯等已成为众多车型的标准配置。同时,随着智能驾驶威廉希尔官方网站

立功科技ISD智能交互车灯威廉希尔官方网站 方案

随着智能汽车的快速发展,车灯产业正在经历从功能车灯向智能车灯转型发展,ISD智能交互车灯凭借成熟的产业链以及不断升级的威廉希尔官方网站

方案,正逐步成为市场主流。本文为大家介绍立功科技ISD智能交互

京东方华灿光电车载LED解决方案助力汽车智慧化、数字化

带来一场视觉赏析。 占据本次展台C位的依旧是京东方华灿光电车载LED芯片解决方案,其涵盖前大灯、车外饰灯、内饰灯、Mini尾灯、刹车灯以及车载背光等多个应用场景。芯片封装方案已通过AEC-Q102实验认证,质量管理体系符合IATF16949车规标准,具有

esp-matter使用idf.py编译light sample报错怎么解决?

在搭建好esp-matter后,编译light sample的时候报错

rck@ubuntu:~/ESP/esp-matter/examples/light$ idf.py build

/home

发表于 06-11 07:04

变频器刹车电阻不同功率如何匹配

在工业自动化系统中,变频器刹车电阻的匹配问题至关重要。刹车电阻作为变频器制动过程中的关键元件,其功率和阻值的选择直接影响到电机的制动效果和变频器的稳定运行。本文将详细探讨变频器刹车电阻不同功率的匹配原则、方法、注意事项及实际应用

极海联合汇昕微推出主控MCU采用G32A1445的贯穿式汽车尾灯解决方案

由刹车灯、倒车灯、转向灯、雾灯等组成的汽车尾灯,既能在光线低暗时发出照明信息,也可向周围环境传递车辆的行驶状态与意图信号,对于行车安全起着至关重要的作用。

车灯防水透气膜坏了有影响吗?2024北京车展智慧车灯防护方案!

大家好,我是微尔斯科技的VILI专注于高分子微孔材料的研发、应用与推广车灯防水透气膜坏了会有一定的影响。车灯防水透气膜的主要作用是防止水分和灰尘进入车灯内部,保证车灯的正常工作。如果

车灯芯片有哪些?

调节车灯亮度的原理通常涉及到 PWM(脉冲宽度调制)威廉希尔官方网站

。PWM是一种调节电子设备(如LED灯)亮度的常用方法,它通过控制信号的占空比来调节电路中的开关元件,从而控制输出信号的平均功率,进而控制亮度

12V-80V车灯芯片都有哪些?

电动车车灯芯片的工作原理可以简要概括为以下几点: 光源:电动车车灯通常使用LED(Light Emitting Diode)作为光源。LED是一种半导体器件,当电流通过LED时,它会发光。 驱动电路

LN2558汽车灯刹车常亮及爆闪二功能车灯方案

我们先看看汽车灯刹车二功能常亮爆闪方案原理电路以下方案: LN2558 是一款外围电路简单,采用自主知识产权的VFPWM 连续工作模式,适用于 8-100V 全电压范围的非隔离式恒流 LED 驱动

DLT8F61SA车灯方案探讨:双路输出与掉电记忆功能

DLT8F61SA车灯方案是汽车照明领域的一个重要创新。以DLT8F61SA芯片为核心,该方案提供了三种独特的灯光模式:小夜灯模式、刹车灯模式和转向灯模式,均以红白灯组合增强夜间行车安全。其最大特色

刹车灯(英文),Pulsing Third Brake Light

刹车灯(英文),Pulsing Third Brake Light

评论