Omni3D Releases Factory 2.0 3D Printer to Enter Industrial Market

While Polish 3D printer manufacturer Omni3D has received attention for the ways that they’ve used 3D printers, applying their expertise to save penguins and build wind turbines, the company’s big news today sees them doing what they do best, building 3D printers.? Omni3D is now releasing their Factor 2.0 3D printer, geared towards the industrial sector with its precision, size, and printing speed.

The Factory 2.0 is the result of two years of research and development and, from the looks of it, that work has paid off.? The FFF 3D printer is capable of printing with an accuracy of .03 mm, 500 mm?(19.7 inches) on each axis, and a traveling speed of up to 350 mm/sec.? Additionally, with a dual extruder, the printer is designed to be capable of using a wide variety of materials, features automatic bed leveling, a closed build chamber, and a 7-inch display, for controlling the printer.

Due to its 10 microprocessors and custom electronics, Omni3D suggests that the Factory 2.0 continuously controls the temperature and humidity of the print chamber and the flow of filament. Other upgrades include the shift from any flexible component, such as rubber belts, to fixed parts, which the company attributes to the increased precision and quality of the machine. The Factory 2.0 also comes with Omni3D’s Mak3r software, which, using predefined settings, “makes the majority [of the] decisions for the user.”

Konrad Sierzputowski, member of the Omni3D Management Board and responsible for the development of the Factory 2.0, says of the new machine, “Dimensional precision is particularly important in industrial productions. The priority for all elements of the production – also including our Factory 2.0 – is accuracy, which guarantees a perfect match between elements and an ideal end product.” He continues, “Similar printers are currently sold on the market only by two American companies. We certainly have the advantage of availability, low price and maintenance costs of our equipment. Factory 2.0 printers operate in an open ecosystem – composites from various manufacturers can be used with them. This definitely improves access to innovative materials and reduces maintenance costs.”

S?awomir Mirkowski, also a member of the Omni3D Management Board, adds, “The majority of devices available on the market use similar solutions, which share the same problems and limitations. Seeing this, we have decided to take the challenge and to fill the market niche. In this way, our offer is now targeted only at entrepreneurs and the broadly understood industry.”

The Factory 2.0 will be available for purchase in Europe and the Americas this September, but the company has already provided the printer to a few companies already.? The machine will not only be used to print wind turbines in California, with the involvement of two Fortune 500 companies, but the Factory 2.0 will also be used in the production line for a “well-known” German auto manufacturer.? While we await the price of and the feedback surrounding the Factory 2.0, from the looks and sound of this printer, it does sound like it will be a worthy competitor and, as the Polish manufacturers continue to make their way into the global market, other European and US companies may be taken by surprise.

Update 7/15/15: I’ve been informed that the Factory 2.0 will be sold for

自动翻译仅供参考

Omni3D的Factory 2.0 3D打印机问世

虽然波兰3D打印机制造商OMNI3D已经注意到他们使用3D打印机的方式,运用他们的专业知识来拯救企鹅和建造风力涡轮机,公司今天的大新闻是他们正在做他们做得最好的事,建造3D打印机。他们的因素2 3D打印机,面向工业部门的精度,尺寸和打印速度。

工厂2.0 3D打印机omni3D

该工厂2.0是两年的研究和开发,结果,从外观上来看,这项工作已见成效?所述FFF三维打印机能够打印具有0.03毫米,500个毫米?(19.7英寸)各轴的精度,并且高达350毫米/秒的行进速度。?此外,具有双挤出机,打印机被设计为能够使用各种不同的材料的,具有自动床流平性,一个封闭的构造腔,和一个7英寸的显示屏,用于控制打印机。

工厂2.0 3D从omni3D双重挤压机打印机

由于其10微处理器和定制电子,Omni3D表明厂2.0连续地控制温度和湿度的打印室和长丝的流动。其他升级包括从任何柔性构件的移位,如橡胶带,以固定的部分,其中,公司属性到机的增加的精度和质量。该工厂2.0还配备了Omni3D的Mak3r软件,该软件,使用预定义的设置,“作出决定用户[中的]多数。”

显示面板从omni3D工厂2.0 3D打印机

康拉德Sierzputowski的Omni3D管理委员会成员,负责工厂2.0的发展,说的新机,“尺寸精度是在工业生产尤其重要。优先生产的所有要素 - 也包括我们的工厂2.0 - 是的准确性,保证元件和理想的最终产品之间的完美匹配“他继续说,”类似的打印机是目前市场上只有两家美国公司出售。我们当然有供应,价格低,我们的设备维护成本的优势。工厂2.0打印机工作在一个开放的生态系统 - 来自不同制造商的复合材料可以与他们使用。这无疑提高了获得创新材料和降低维护成本。“

S‘awomir Mirkowski,所述Omni3D管理委员会也成员,补充道,“大多数可在市场上的设备使用的类似的解决方案,其共享相同的问题和限制。看到这种情况,我们已经决定接受挑战,并填补了市场地位。这样一来,我们的报价,现在的目标只有在企业家和广义地理解产业“。

模型的3D打印从omni3D厂2.0 3D打印机

该工厂2.0将可以购买在欧洲和美洲今年九月,但该公司已经提供了打印机的几个公司了。?该机不仅将用于打印的风力涡轮机在加利福尼亚州,与两家世界500强企业的参与,但工厂2.0也将被用于生产线的“知名”的德国汽车制造商?虽然我们等待的价格和工厂2.0周围的反馈,从长相和声音本机,它听起来就像这将是一个有价值的竞争对手,并为波兰制造商继续作出自己的方式进入全球市场,其他欧洲和美国的公司可能会措手不及。

-

3D打印

+关注

关注

26文章

3549浏览量

109080

发布评论请先 登录

相关推荐

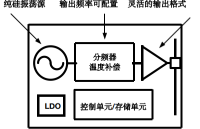

有源晶振在3D打印机应用方案

领麦微红外测温传感器在小型光敏3D打印机中的创新应用

应用在3D打印机的BD系列金属连接器

2024年含直线电机3D打印机在内共出口182.9万台

3D打印汽车零部件建模设计3D打印服务

UltiMaker正式推出了工业级3D打印机—UltiMaker Factor 4

YXC晶振 32.768KHz石英振荡器,封装3225,应用于3D打印机

Omni3D的Factory 2.0 3D打印机问世

Omni3D的Factory 2.0 3D打印机问世

评论